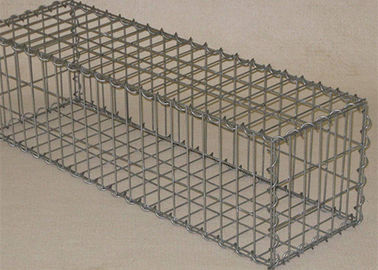

Product Description:

The Welded Stone Box retaining wall system is a cost-effective and durable way of creating a long-lasting retaining wall, with a decorative facade. The gabion effect is achieved by fixing vertical supports to the exposed face of your precast retaining wall, This can then be filled with any gabion stone filling to create a strong, durable and attractive retaining wall.

| Welded Gabion specifications |

| Wire diameter:3.0-6.0mm |

| Size M |

Mesh size MM |

DiaphragmsNo. |

CBM |

| 1.0*1.0*0.5 |

50*50 75*75 50*100 100*100 |

0 |

0.5 |

| 1.0*1.0*1.0 |

0 |

1.0 |

| 1.5*1.0*0.5 |

0 |

0.75 |

| 1.5*1.0*1.0 |

0 |

1.5 |

| 2.0*1.0*0.5 |

1 |

1.0 |

| 2.0*1.0*1.0 |

1 |

2.0 |

| 3.0*1.0*0.5 |

2 |

1.5 |

| 3.0*1.0*1.0 |

2 |

3.0 |

| 4.0*1.0*0.5 |

3 |

2.0 |

| 4.0*1.0*1.0 |

3 |

4.0 |

| The specifications can be customized. |

The welded mesh stone box system is quick and easy to install, we supply all the necessary fixings required to create the gabion effect. Unlike traditional gabion baskets, the unique design of the stone box system will ensure that the gabion face will not misshape over time.

By using a mesh and stone facing, your retaining wall will have a more natural appearance than a traditional precast concrete wall and will fit better into its surroundings.

How to install welded gabion box:

1) Foundation preparation

The foundation on which the gabions are to be placed shall be cut or filled and graded as required. Surface irregularities, loose material, vegetation, and all foreign matter shall be removed from foundation surface area. Extra care should be taken with foundation preparations in order to ensure a level and smooth surface.

2) Assembly

Rotate the gabion panels into position and join the vertical edges with fasteners for gabion assembly. Where spiral fasteners are used, crimp the ends to secure the spirals in place. Where C ring type alternate fasteners are used for basket assembly, install the fasteners at a maximum spacing of 150 mm. Use the same fastening procedures to install interior diaphragms where they are required. Interior diaphragms will be required where any inside dimension exceeds 1m for gabion baskets. Diaphragms will be installed to assure that no open intervals are present that exceeds 1m.

3) Placement

Place the empty gabions on the foundation and interconnect the adjacent gabions along the top, bottom, and vertical edges using spirals or C rings.

Modular Assembly

Gabion cages can be built in a modular method by eliminating an end panel for each cage so no two panels need be connected together. The same method may also be used for successive courses including lid and base panels. Interconnect each layer of gabions to the underlying layer of gabions along the front, back, and sides.

4) Filling

Staking of the gabions may be done to maintain the established proper alignment prior to the placement of rock. Connecting lacing wire and other fasteners shall be attached during the filling operation to preserve the strength and shape of the structure.

Internal connecting cross-tile (stiffener) wires shall be placed in each unrestrained gabion cell, including gabion cells left temporarily unrestrained. In welded mesh gabions these crossties or stiffeners will be placed across the corners of the gabions providing diagonal bracing. Lacing wire or preformed wire stiffeners may be used.

The gabions shall be carefully filled with rock, ensuring alignment, avoiding bulges, and providing a compact mass that minimizes voids.

The last layer of rock shall be uniformly leveled to the top edges of the gabions. Lids shall be placed over the rock filling using only approved lid closing tools as necessary. The use of crowbars or other single point leverage bars for lid closing is prohibited due to the potential for damage to the baskets. The gabion lid shall then be secured to the sides, ends, and diaphragms with spiral binders, approved alternate fasteners, or lacing wire wrapped with alternating single and double halfhitches in the mesh openings.

Applications:

Gabions are used in many situations including the stabilization of earth movement and erosion, river control, reservoirs, canal refurbishment, landscaping and retaining walls. They can be manufactured in welded mesh or woven wire. Welded mesh gabions are faster to erect and do not need tensioning. This allows them to keep their shape, to be free from bulges and depressions and fit easily against the wall.

Packing details

Packing: In pallet or in bundle, put in wooden case or cartons,as buyer's requirement.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!